This article is written by Uthra Rajgopal, who worked with Five P to develop their website and promotional material during a textile exploration trip around India last year. An art history post- graduate and currently a lecturer at Manchester Metropolitan University, Uthra is conducting research into Khadi and Handloom in India, and will be presenting at the forthcoming Textile Society of America conference in October.

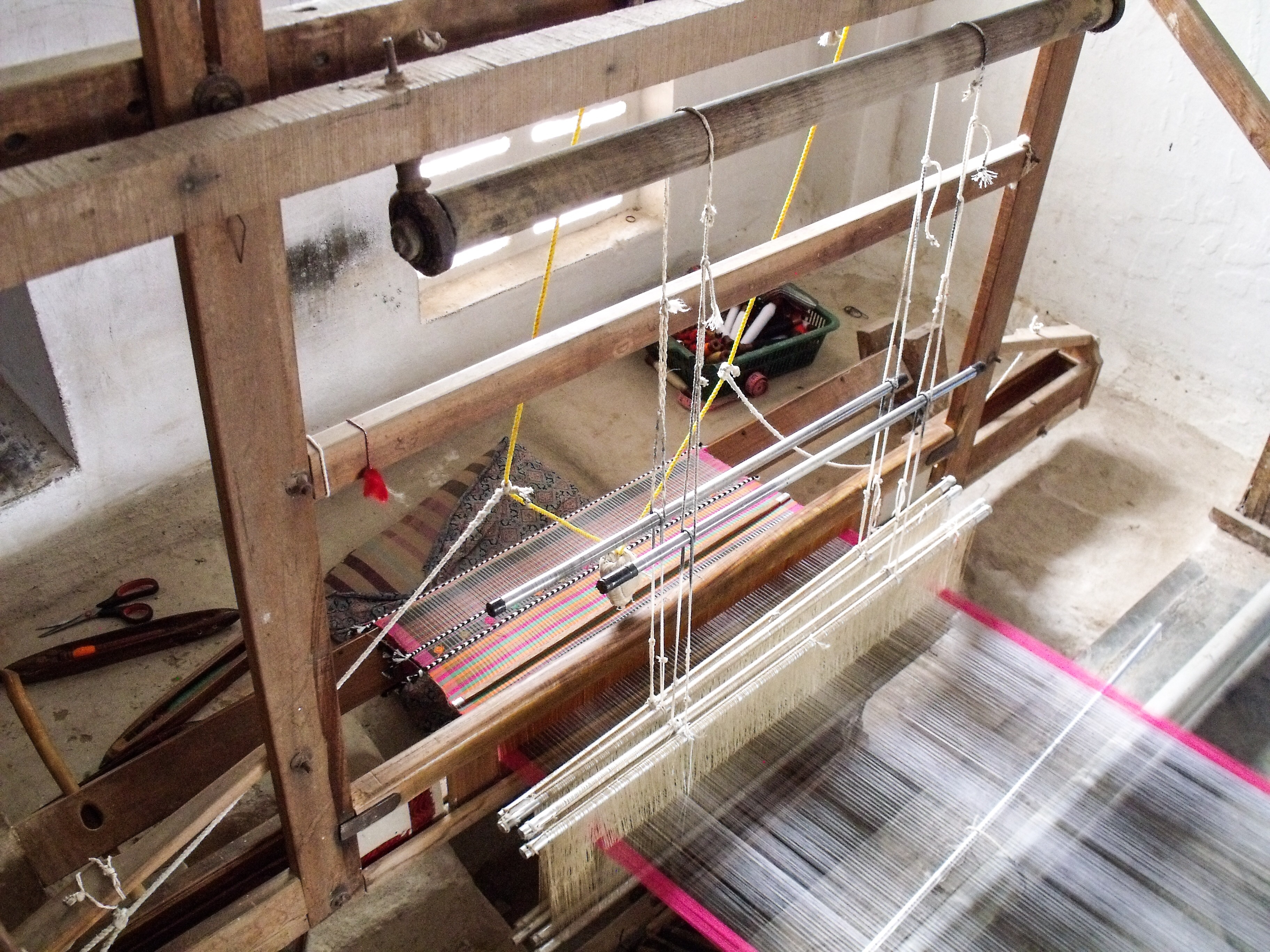

Above Photo: Mr.Kandasamy on a jacquard loom in the Five P workshop. Photo: Ruth Clifford

Chenimalai is a small town about 25 km from Erode, at the centre of the ‘cotton belt’ between the textile hubs of Coimbatore and Salem in Tamil Nadu. The area has a long history of textile production and today it comprises of a large population of handloom and powerloom weavers working mainly for cooperative societies or large factories. Industrialisation dramatically transformed this area in the middle of the 19th century, but the craft of handloom survived this and the severe competition from the British imports, by constant innovation and diversification and changes in organisations and technology.

In the decades before 2008, weavers had stable work through large, regular export orders, most notably from IKEA. But around 2008, IKEA and other large merchant exporters turned to powerlooms which could produce similar products in less time. As weavers had been producing the same products for so long, many were unable to adapt to different markets. Further, the large amount of government-run cooperatives keep many weavers under tight contracts, so that private enterprises are unable to work with them, yet the societies’ marketing input is often ineffective, and in recent years they have not been able to provide weavers with enough work.

Handloom weavers need to escape the competition of powerloom by finding high-end markets that appreciate the unique qualities of handloom. This is where FiveP came in.

Five P are based in Chennimalai and work with handloom weavers to provide a long term strategy for a sustainable future. The ‘Five Ps’ stands for Promote, Protect, Preserve, for our Prosperity and Posterity. The idea initially came from Mr Devarajan, the owner of a family-run construction business. Growing up in Chennimalai, Mr Devarajan would often see and hear the weavers at work. About four years ago, Mr Devarajan recognised that the handloom weaving sector in Chennimalai was in severe decline and so he decided to set up a business to give something back to his home town.

In 2012 Mr Sampath Kasirajan, a long-standing friend and colleague of Mr Devarajan, was enlisted to carry out a feasibility study on the area (read the resulting report here). The study revealed that up until 2010 the handloom weavers had been supplying bed sheets for international markets but thereafter they lost out to the powerloom sector, leaving them with no option but to work within a cooperative system. The weavers were despondent and did not see any viable future in the long term and certainly not for the next generation.

Five P then put in place a pilot project which brought together the handloom weavers with designers from Australia. Together they produced a variety of patterns in denim and created a capsule garment collection. Encouraged by the success of this project, land was purchased by Mr Devarajan and Five P began to take shape.

Five P now operates on a 12 acre site in Chennimalai and has two enormous purpose-built loom sheds. They are light, airy and run on renewable energy. There are approximately 25 looms, including a small number of jacquard looms in each shed, which allows greater flexibility for trial runs. The entire site has been built to comply with environmental standards under India’s Green Certificate scheme. Five P is currently managed by Shree Bharathi, Mr Devarajan’s daughter. Shree is supported by a dedicated team and works with closely with designers to meet their exacting standards.

The fabrics produced by Five P are typically linen, organic cotton and recycled cotton. To date Five P has supplied home textiles and apparel nationally and internationally, including the UK and Australia. The organisation is in its early stages, and has ambitions to connect with buyers and designers globally, seeing a strong potential in the global market for high-end, ethical and hand-made products.